Short-term and long-term capability - Sigma Level

The short-term capability covers a relatively short period of time and typically consists of 30 to 50 measured values that are recorded in direct succession. This results in the short-term process capability index, also known as machine capability. With short-term capability, the best possible process performance is to be determined by keeping disturbance variables, i.e. causes for scatter, as far away as possible. When considering a rather short period of time (days, weeks), the influences on the variation are reduced, which can be caused, for example, by different shifts, batches or temperature fluctuations.

The short-term capability thus reflects the best possible process.

In the case of long-term capability, the process quality is assessed by statistical evaluation over a relatively long period of time (weeks, months), especially with the use of control charts. The data acquisition typically comprises at least 100 - 200 measured values. Long-term capability is affected by far more disturbance variables that lead to process fluctuations. It is therefore always lower than the short-term capability.

Whether short-term or long-term data is available depends very much on the actual product and the respective throughput times. This means that this assessment must be differentiated from case to case.

The short-term capability covers a relatively short period of time and typically consists of 30 to 50 measured values that are recorded in direct succession. This results in the short-term process capability index, also known as machine capability. With short-term capability, the best possible process performance is to be determined by keeping disturbance variables, i.e. causes for scatter, as far away as possible. When considering a rather short period of time (days, weeks), the influences on the variation are reduced, which can be caused, for example, by different shifts, batches or temperature fluctuations.

The short-term capability thus reflects the best possible process.

In the case of long-term capability, the process quality is assessed by statistical evaluation over a relatively long period of time (weeks, months), especially with the use of control charts. The data acquisition typically comprises at least 100 - 200 measured values. Long-term capability is affected by far more disturbance variables that lead to process fluctuations. It is therefore always lower than the short-term capability.

Whether short-term or long-term data is available depends very much on the actual product and the respective throughput times. This means that this assessment must be differentiated from case to case.

Sigma Level

In addition to the conventional process capability indices such us Cp, Cpk, Pp, Ppk, process capability can also be expressed with the sigma level.

The sigma level Z describes how many standard deviations can be placed between the mean value and the tolerance limit of a process.

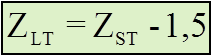

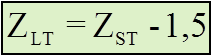

If you want to use short-term data to make statements about long-term capability, you can use the following formula as a projection:

The value 1.5 was determined empirically from manufacturing processes and considers that more influences affect the process in the long term than over a shorter period of time. However, the 1.5 sigma difference is not a constant, but can vary depending on the short-term value. The difference between (extreme) short-term and long-term observation is 1.5 on average.

The value 1.5 was determined empirically from manufacturing processes and considers that more influences affect the process in the long term than over a shorter period of time. However, the 1.5 sigma difference is not a constant, but can vary depending on the short-term value. The difference between (extreme) short-term and long-term observation is 1.5 on average.

Short-term and long-term capability - Sigma Level in PDF format

Further training opportunities ...

... can be found in the Education and Training section!

... can be found in the Education and Training section!

...... or simply give us a call or send us an e-mail. We will be happy to help you!

...... or simply give us a call or send us an e-mail. We will be happy to help you!