Basics of Measurement System Analysis (MSA)

We obtain data by measuring objects, situations or phenomena.

We use this data to classify, describe, improve or control processes and procedures.

We use the term "Measurement System" for all systems that provide data.

It does not matter whether data is actually "measured" in the classical sense or whether data is generated on the basis of experience, evaluations and rules.

In practice, we check our measuring systems far too infrequently, and this despite the fact that the usability of the measuring systems is often very poor. Even a newly calibrated measuring device can be unusable for the measurement for which it is used.

Why do we need to check the measurement systems?

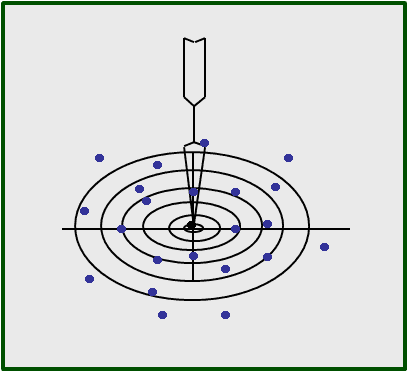

We observe our processes by collecting measurement data. The observed variation of our processes thus consists of the variation of the actual process plus the variation of the measurement system. If the measurement system scatters too much, the actual process variation cannot be detected!

We observe our processes by collecting measurement data. The observed variation of our processes thus consists of the variation of the actual process plus the variation of the measurement system. If the measurement system scatters too much, the actual process variation cannot be detected!

What is part of the measuring system?

Measuring tools:

- Hardware (measuring instruments, test equipment, gauges, ...)

- Software (databases, evaluation software, algorithms...)

All procedures for the application of the tools:

- Test persons (experience, skills, understanding...)

- Setup and implementation of procedures (rules, instructions, ...)

- Offline calculations and data entry

- Frequency and method of calibration

Environment:

- Space, cleanliness,

- lighting conditions,

- disturbances, noise, stress...

We want to check whether the measurement system is appropriate

- in the environment in which it is used,

- by the people who operate it,

- for the real parts that are to be measured,

- that is, for the measurement task.

MSA's can be carried out for:

Quantitative variables (GR&R) for numbers and units of measurement as well as for

Qualitative factors (attributes) through subjective inspections such as seeing, feeling, smelling, hearing.

In both cases, the influence of repeatability and reproducibility on the variation of the measurements is determined.

One-day Training

Measurement System Analysis

Learn more in one day about the topics MSA

- Basics

- MSA Typ 1

- MSA Typ 2

- MSA for attributive data

In addition to the theoretical basics, we use concrete examples and practical exercises to convey the direct reference to application in day-to-day business.

Learn more in one day about the topics MSA

- Basics

- MSA Typ 1

- MSA Typ 2

- MSA for attributive data

In addition to the theoretical basics, we use concrete examples and practical exercises to convey the direct reference to application in day-to-day business.

Basics MSA in PDF format

Further training opportunities ...

... can be found in the Education and Training section!

... can be found in the Education and Training section!

...... or simply give us a call or send us an e-mail. We will be happy to help you!

...... or simply give us a call or send us an e-mail. We will be happy to help you!