Design for Six Sigma Training (DFSS)

Duration 3 days

The Design for Six Sigma training is primarily aimed at those involved in development and serves the goal-oriented development of products and processes. The training covers the following focal points:

- Recording of all customer requirements

- Identification and concentration on quality-critical features

- Shorter and plannable development times

- Linking creative solution finding with structured concept selection.

- Development of innovative, reliable and economical products and processes.

Participants receive a detailed basic knowledge of the fundamental orientation of Design for Six Sigma as well as comprehensive methodological knowledge for the application of tools for the customer- and process-oriented development of products and processes.

Training contents

- Design for Six Sigma

- overview - The project mission

- Stakeholder-Analysis

- SIPOC

- Voice of the Customer (VOC)

- VOC-Plan

- Kano-Modell

- CTQ - driver tree

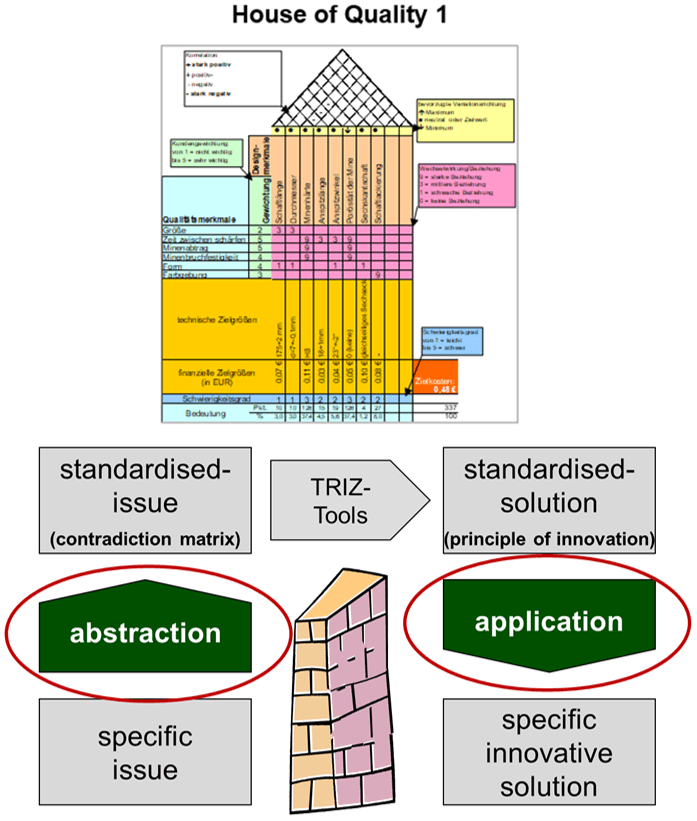

- practical implementation - Quality Function Deployment (QFD)

- House of Quality

- Implementation of a QFD - Design Scorecard

- Solution finding, Creativity techniques

- Different creativity techniques and their application - Concept selection, solution selection, Pugh Matrix

- TRIZ

- Fields of application, essential

methods - Statistical tolerancing

- Robust Design, simulation

- Poka Yoke

- Solution risks and implementation

- Design for Six Sigma

- overview - The project mission

- Stakeholder-Analysis

- SIPOC

- Voice of the Customer (VOC)

- VOC-Plan

- Kano-Modell

- CTQ - driver tree

- practical implementation - Quality Function Deployment (QFD)

- House of Quality

- Implementation of a QFD - Design Scorecard

- Solution finding, Creativity techniques

- Different creativity techniques and their application - Concept selection, solution selection, Pugh Matrix

- TRIZ

- Fields of application, essential

methods - Statistical tolerancing

- Robust Design, simulation

- Poka Yoke

- Solution risks and implementation